PLC Software Integration

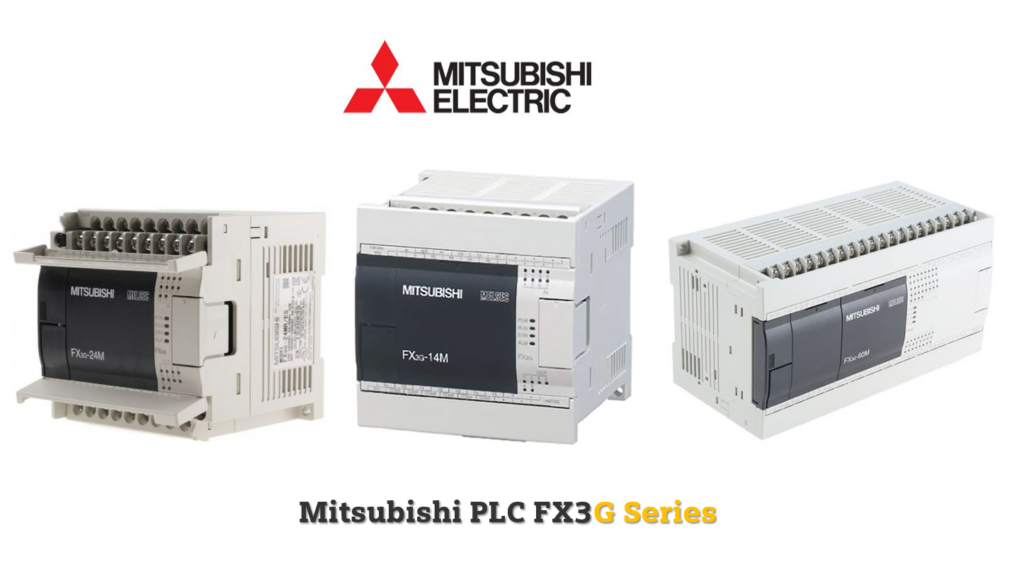

Industrial automation controller

PLC Software Integration

PLC is an automatic control machine in industrial plants. Was created and developed to replace the Relay circuit due to the desire to have a low-cost control device that can be used for many purposes. and can easily learn to use

We can create circuits or control models by entering command programs into the PLC. It can also be used with other devices such as barcode readers and sticker printers.

At present, in addition to the PLC being used alone (Stand alone), many PLCs can also be connected together (Network) to control the system's operation to be more efficient. It can be seen that the use of PLCs It is very flexible, so in factories more and more are switching to using PLCs.

ประโยชน์ของ PLC

Components are solid state.

high reliability

Includes timer and counter software.

reduce hardware usage

Easy to adjust such as time value, count value

It has a module structure.

flexible installation

easy to install

Reduce hardware costs

Can be extended

With Remote I/O Station

Eliminate Wiring long electrical conduit

There is software that is Relay.

reduce hardware usage

Reduce the cost of electrical wiring

Input and Output are quick cut.

When replacing, do not mess with the electrical wiring within the system.

Able to reprogram the memory

easy to change

The controls are flexible.

There is a microprocessor based control.

have the ability to communicate

has a high performance level

increase the quality of production

There are many useful functions.

is small

Requires little installation space

There is a wide variety of Input and Output connectors.

control a variety of devices

reduce the limits of control

Input and Output connectors are Module type.

Make the control panel look neat

Ease of wiring

easy to maintain

System variables are stored in data memory.

easy to manage maintenance

Data can be sent out in the form of a report.

ภาพรวม ผลิตภัณฑ์